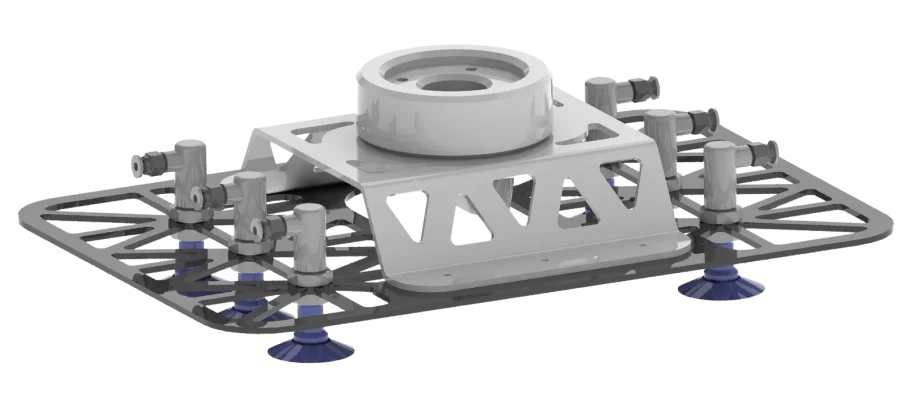

TR1: Mobile, Modular and Configurable Collaborative Robotic Cell

Modular, flexible and mobile todrobot robotic island. Extreme precision of welding execution, palletizing, deburring and more.

Modular, flexible and mobile todrobot robotic island. Extreme precision of welding execution, palletizing, deburring and more.

The robot is able to work around the clock, extremely simple to set up

Built to ensure long life and high performance with reduced recharge times

Small size and high adaptability help optimize internal logistics

Simplified maintenance thanks to quick battery replacement

The flexibility of a robotic arm, the mobility of an autonomous robot and the features of artificial intelligence and machine learning.

Todrobot is the ideal solution for process automation, both for small and medium-sized batches and for situations where the configuration is constantly changing.

With its quick activation and intuitive control system, the flexible todrobot robot cell offers easy access to automation.

Whether for assembly, pick-and-place operations or training purposes, todrobot assists you precisely where you need it most.

You can choose from a wide range of accessories to create a customised package according to your specific needs.

The TR1 is a robot designed to work together with human personnel, positioning itself with millimetre precision with respect to objects. It reduces errors and wrong decisions, ensuring an automated and continuous production flow.

The robot is able to work around the clock, extremely simple to set up

Built to ensure long life and high performance with reduced recharge times

Small size and high adaptability help optimize internal logistics

Simplified maintenance thanks to quick battery replacement

With a wide selection of accessories available and the freedom to customize the machine, you will be able to respond to the specific needs of the use case.

Thanks to its variable configurability and fast retooling times, you will be able to enjoy maximum flexibility in your processes and fully exploit the potential for modernizing your production.

Possibility to easily integrate additional components into the workbench of the flexible robotic island, based on specific wishes and needs.

Reduction of times and errors in order processing which leads to work efficiency and cost reduction.

By replacing the tools you can adapt the system to your production process. It can carry out picking & place from shelves and workstations by reprogramming it according to future needs.

It does not require structural modifications and masonry works of the warehouse. Adaptable to future changes in the warehouse working area.

Just like an operating system, it allows the installation of multiple elements that make it capable of satisfying multiple operational needs. The TR1 robotic island serves as the basic operating system for the different needs it can be used for.

The composition operations of the TR1 are Plug&Play, that is, simple, immediate and immediately functional!